marra watson

Moderator

Got me there Marra,:wondering:

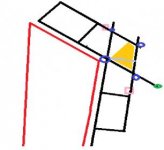

you would build you ya bay with the inside ledger sailing past the corner of the building like you would with a return. go to the end of the inside ledger and put a temp standard in to keep your level. now go round the corner and sit inside ledger on the ledger with a temp standard fixed to it just like a return with enough sailing over to cath the out side ledger of the first bay you built once you have built the bay from the return you now go and place a double on the the ledger with the temp standard place in you standard with the retun ledger you place the the single on the standard . sleve out both out side ledger were they meet again place a standard on this tg drawing of mine green is your temp standard, blue are your standards pink are your sleves the yellow box is were you need a few different sized board the grey line on the yellow box si were you would start you return flight this oic may help