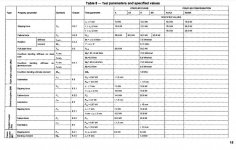

The pull apart force Fpd is supposed to be shown in table 5.15 in TG20 but isn't. I'm surprised that I don't have an amendment to correct the omission but I guess that no-one reads that part of the damned book.

I know that the pull apart force on a double is 12.2 kN (working load) so I can use clause 5.8.3 if I want to for doubles but I can't find any requirements for swivels.

Does anyone know what they are tested to or if there is a standard that gives this so that I can take advantage of a known figure or are they forbidden from taking pull apart loads?

I know that the pull apart force on a double is 12.2 kN (working load) so I can use clause 5.8.3 if I want to for doubles but I can't find any requirements for swivels.

Does anyone know what they are tested to or if there is a standard that gives this so that I can take advantage of a known figure or are they forbidden from taking pull apart loads?