Can any one point me in the right direction ?

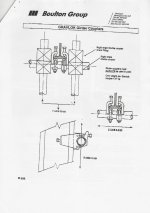

I was asked yesterday to build a scaffold in the top of a lift shaft approx 4 m high , the man said his normal London based scaffolders use SKs to fix to the vertical guides of the lift mechanism, and the build off of these . I told him that I did not think SKs had a safe working load in vertical slip resistance and pulled off the job . I have seen clamps that Otis use to secure lift car to the guide rails but these have three bolts and come with a test certificate and new bolts every time they are used . They are meant to tale a high load but this bloke said SK would do . Any ideas ?

I was asked yesterday to build a scaffold in the top of a lift shaft approx 4 m high , the man said his normal London based scaffolders use SKs to fix to the vertical guides of the lift mechanism, and the build off of these . I told him that I did not think SKs had a safe working load in vertical slip resistance and pulled off the job . I have seen clamps that Otis use to secure lift car to the guide rails but these have three bolts and come with a test certificate and new bolts every time they are used . They are meant to tale a high load but this bloke said SK would do . Any ideas ?